Emission control solutions for LPG, CNG and gasoline engines

Proposed Rule Calls for Reduced Exposure to Diesel Particulate for Underground Coal Miners

MSHA News Release No. 98-0414

Mine Safety and Health Administration

Contact: Rodney Brown

Phone: (703) 235-1452

The Mine Safety and Health Administration (MSHA) has proposed new health standards for underground coal mines that use equipment powered by diesel engines. This proposal is designed to reduce the health risks to underground coal miners associated with the high levels of diesel particulate matter found in underground mines.

Diesel particulate matter, or DPM, is composed of very small particles–usually less than a micron in size–which can readily penetrate into the deepest recesses of the lung. Based upon a review of the scientific literature, MSHA has concluded that miners who are exposed to high levels of DPM face a significantly higher risk of dying from such diseases as lung cancer, heart failure and other cardiopulmonary problems than do miners who are not so exposed. MSHA has also concluded that miners exposed to such levels of DPM face a significantly greater risk of incurring a variety of other health problems (e.g., coughs, headaches) which could result in lost work time and could impact job safety.

Underground coal mines are confined environments which, despite ventilation requirements, tend to accumulate significant concentrations of particles and gases–both those produced by the mine itself (e.g., methane gas) and those produced by equipment used in the mine.

MSHA estimates that more than 13,000 underground coal miners are exposed to diesel emissions. Some underground miners are exposed to concentrations of DPM that are more than 10 times as high as the average workplace exposures recorded in any other industry.

“Underground miners are among the occupational groups most highly exposed to diesel exhaust,” said J. Davitt McAteer, assistant labor secretary for mine safety and health. “The goal of the proposed rule is to reduce underground coal miners’ exposures to attain the highest degree of health protection that is feasible.”

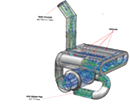

The proposed rule would require mine operators to install and maintain high-efficiency particulate filters on the most polluting types of diesel engines found in underground coal mines and to train miners about the hazards of DPM exposure.

Within 18 months after the final rule is published, permissible diesel-powered equipment must be equipped with a system that removes 95 percent of the particulate material emitted from the engine. Within 30 months after the final rule is published, non-permissible heavy duty diesel-powered equipment must have such a control system. Heavy duty equipment is defined as equipment that cuts or moves rock or coal, performs drilling or bolting functions, moves longwall components, and transports diesel fuel or lube units.

MSHA estimates that the compliance cost per year to the underground coal industry is about $10 million. For a mine employing fewer than 20 miners, the estimated annual cost is about $8,000; for large mines, the estimated cost is about $58,000.

DPM exposure levels at surface mines, although much lower than underground mines, can still present health risks. MSHA will address such concerns through educational and outreach efforts to protect coal miners at surface operations. Furthermore, by separate notice, MSHA will soon propose a rule to protect miners in underground metal and nonmetal mines from DPM.

In the fall of 1995, MSHA held a series of workshops to obtain input from the mining community on ways to reduce miners’ exposure to diesel exhaust. Those practical ideas were used to produce “Practical Ways to Reduce Exposure to Diesel Exhaust in Mining–A Toolbox.” This toolbox is available on MSHA’s Home Page on the Internet. The address is www.msha.gov.

Printed copies of the Toolbox will be available soon.

Diesel-powered equipment was introduced into underground mines in the 1960’s to facilitate delivery of supplies and material. The health risk of diesel particulate was first brought to the attention of MSHA more than 15 years ago. On Oct. 25, 1996, MSHA issued safety standards to protect miners against fires, explosions, toxic exhaust gases, and other potential safety hazards of diesels in underground coal operations. The 1996 rule requires MSHA-approved diesel equipment at the working face, low sulfur fuel, monitoring of toxic gaseous emissions, and engine maintenance by persons adequately trained for the task so that engines will run cleaner.

MSHA’s proposed rule to control DPM exposure of underground coal miners was published in the Federal Register on Thursday, April 9. Comments on the proposed rule must be submitted by Aug. 7, 1998, and may be transmitted by electronic mail, fax, or mail, or dropped off in person at any MSHA office. The electronic mail address is [email protected]. The fax number is (703) 235-5551. The mailing address is MSHA, Office of Standards, Regulations, and Variances, Room 631, 4015 Wilson Boulevard, Arlington, VA 22203-1984.