Emission control solutions for LPG, CNG and gasoline engines

EPA Funded JAXPORT Diesel Emissions Reduction Project Completed by Nett

21-October-2013 / On May 31st 2013, Nett Technologies Inc. of Mississauga, Ontario, Canada won the bid to design, manufacture and install nineteen Diesel Oxidation Catalysts (DOC) onto several large container cranes, generator, forklift and trucks owned and operated by the Jacksonville Port Authority (JAXPORT).

JAXPORT is located in Jacksonville, Florida and is an independent seaport authority created by the Florida State Legislature to operate as a landlord, managing its equipment, upkeep, and the continued expansion and improvement of its port facilities. The JAXPORT emissions retrofit project was made possible by a $570,000 grant awarded by the Florida Department of Environmental Protection and funded by the United States Environmental Protection Agency (EPA). This grant was established to assist JAXPORT’s efforts to voluntary reduce diesel emissions at their Talleyrand and Blount Island Marine terminals. The installation of these retrofit catalysts will reduce overall JAXPORT emissions by 10 tons per year.

“The JAXPORT project presented its own share of unique installation challenges. If it weren’t enough that the project required completion before the Atlantic hurricane season; there were also a wide variety of equipment types, engine sizes, positions and available installation space making this project truly unique. Each of the individually custom designed DOC systems needed to be installed with the utmost of skill and precision. Thankfully, Beard Equipment with the assistance of JAXPORT were instrumental in overcoming this challenging installation.” explains Mr. Stephen Ashton, Lead Design Engineer at Nett Technologies.

“It was definitely a rewarding project, especially given the fact that we only had 90 days to complete the project from start to finish. Nonetheless, with the combined efforts of JAXPORT and Beard Equipment, we were able to complete this project within the stipulated budget and timeline. All stakeholders involved in this project have every reason to celebrate its successful completion.” continued Mr. Ashton.

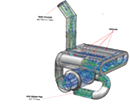

As an innovator of port emission control systems, Nett Technologies Inc. has almost 20 years experience in the design, development and manufacturing of custom retrofit solutions that control Particulate Matter (PM), Nitrogen Oxides (NOx), Hydrocarbons (HC), and Carbon Monoxide (CO) emissions from all compression and spark-ignited engines. Discover today the many ways Nett Technologies can help your organization meet emission regulatory compliance. Visit Nett Technologies online at www.nett.sayahnet.com for all your emission control solutions.

Videos of this voluntary reduction can be view at http://youtu.be/0WazfpET5HU and http://youtu.be/6sVBI4xWcsQ

For further information, please contact:

Nett Technologies Inc.

[email protected]

(800) 361-6388

About Nett Technologies Inc.

Located in the Greater Toronto Area, Nett Technologies Inc. is an innovative emissions control company that specializes in the design, development and manufacture of pollution control solutions for today’s compression and spark-ignited engines for both the OEM and retrofit markets. Sold and supported globally, Nett Technologies Inc., develops and manufactures proprietary catalytic solutions that use the latest in diesel oxidation catalyst (DOC), diesel particulate filter (DPF), selective catalytic reduction (SCR), engine electronics, stationary engine silencer, exhaust system and exhaust gas dilution technologies. Our reliable and real-world emission solutions will extend the useable life of existing equipment while allowing you to avoid costly future replacements. During our manufacturing processes, we use the best of materials, innovative product design and workmanship. We manufacture emission control solutions that are California Air Resources Board (ARB) and the U.S. Environmental Protection Agency (EPA) verified. As the emission control authority, we are here to help you navigate through the hassles and complexities of emission control compliance. We are the industry leader and innovator of direct-fit emission control solutions to the construction, mining, material handling, power generation, utility, transit and trucking, marine and locomotive industries achieving new standards in emission control excellence.