Emission control solutions for LPG, CNG and gasoline engines

NEES™220 – Adjustable 24-Volt Digital Air-to-Fuel Ratio Controller for CNG Gensets

Nett Technologies Inc. has introduced a new version of their newest air-to-fuel ratio controller in the Nett Emissions Eliminator System line, the NEES™220. The NEES™220 is the new 24-volt version of the NEES™210 (12-volt) making the NEES line compatible with both types of engine electrical systems. The NEES™210/220 incorporates the latest and most economically efficient technology for emission reduction from CNG fueled Generator-Sets. Fully self-diagnostic with built-in LED indicators, the NEES™210/220 control unit provides a precise measurement of the ratio of the air/fuel mixture to maximize the performance of closed loop configured Nett® 3-way catalyst systems.

Unlike the NEES™200 (designed for LPG systems) the NEES™210/220 has a built-in A/F ratio control adjustment feature allowing the technician to manually adjust the parameters of the “catalyst window” without compromising the performance of the catalyst system.

The built-in diagnostic functions featured by the controller, allow constant visual monitoring of the engines’ fuel system by the technician. Such innovative technology eliminates the costly requirement for additional calibration monitors.

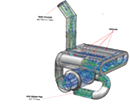

The Nett® closed loop emission control system for CNG Gen-Sets includes a three-way catalytic converter/muffler and the NEES™210/220 control system, which incorporates an oxygen sensor, solenoid and the control module. The system efficiently removes carbon monoxide, nitrogen oxides, and hydrocarbons from CNG exhaust gases.

The three-way catalyst in conjunction with an air-to-fuel ratio controller is the most effective method of cleaning spark-ignition engine exhaust gases available today. To ensure high efficiency of the three-way catalyst, the air-to-fuel mixture must be precisely controlled within a narrow “catalyst window”. The controller receives a feedback signal from the oxygen sensor, which is placed at the inlet of the catalyst. Stoichiometric air-to-fuel ratio control is realized by a solenoid valve which biases pressure on the fuel converter diaphragm using vacuum, thus controlling the amount of fuel supplied to the mixer. The NEES™210/220 air-to-fuel ratio controller features a number of diagnostic functions. LED lights provide a signal in the case of system failure, as well as an indication of several important performance parameters, such as the mixture composition.

Designed as an OEM or retrofit kit for CNG engines, the NEES™210/220 includes all components necessary for installation, such as fittings, tubing, and complete wiring, along with self-explanatory installation instructions. The system works on engines with any number of cylinders and with all common CNG fuel systems without the need for modifications.