BlueCAT™ 200

3-Way Catalytic Converters for LSI Features

California Air Resource Board (CARB) verified system

California Air Resource Board (CARB) verified system- The system is designed to operate on gaseous (LPG, "propane", "propane-butane" and CNG) fueled Large Spark Ignited (LSI) engines

- Ideal for construction, material handling, and utility industries

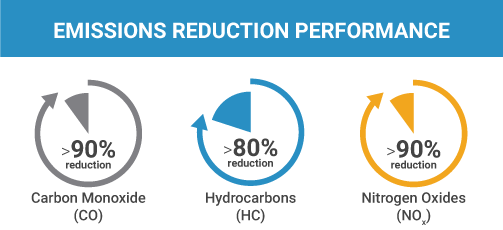

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC) and Oxides of Nitrogen (NOx)

- Direct-fit replacement for the original muffler which simplifies the installation and saves time

- Air/Fuel ratio Controller that goes with the system helps to control and monitor the system performance

- BlueCAT™ 200 catalytic muffler matches or surpasses the original muffler in sound attenuation and backpressure characteristics with the addition of superior emissions performance

BlueCAT™ 200 - Technology

The BlueCAT™ 200 is a Retrofit Emissions Control System which has been verified by the California Air Resources Board (CARB) for installation on uncontrolled gaseous fueled Large Spark Ignited (LSI) engines. BlueCAT™ 200 systems control exhaust emissions and noise from industrial forklift trucks and other spark ignited rich-burn (stoichiometric) engines. Nett Technologies’ BlueCAT™ 200 practically eliminates all of the major exhaust pollutants: Carbon Monoxide (CO), Hydrocarbons (HC) and Oxides of Nitrogen (NOx) from engine exhaust.

The BlueCAT™ 200 system consists of a 3-Way Catalytic Converter/Muffler, and a digital Air/Fuel Ratio Controller (A/F). The entire system is designed for quick and easy installation:

- an oxygen sensor port is built into the converter/muffler

- the self-diagnostic Electronic Control Unit (ECU) comes complete with all wiring and connectors

- comprehensive instructions, refined by hundreds of installations, are included

The BlueCAT™ 200 ECU is packaged in a rugged metal enclosure suitable for dash or engine compartment installation. The controller incorporates an on board diagnostic system, which allows constant monitoring of the operation and simplifies set-up. The combination of lights built directly into the unit provides an indication of controller operation without the need for additional monitoring tools. The diagnostic functions include a power and failure light, a warm up and O2 sensor light, and a set of lights to monitor the percentage of A/F ratio modulation. It also includes a dashboard-mountable warning light to alert the operator in case of system failure and to prevent the release of excessive emissions.

The BlueCAT™ 200 and BlueCAT™ 300 both use the same basic technology to operate, and are externally identical except for the identification plates. Internally the BlueCAT™ 300 uses a more advanced catalyst and slightly different tuning of the control circuitry for improved emissions reductions.

In cases when you have a forklift fleet, use our Large Spark Ignited (LSI) engine calculator and discover the available fleet emission control solutions.

BlueCAT™ 200 - Performance

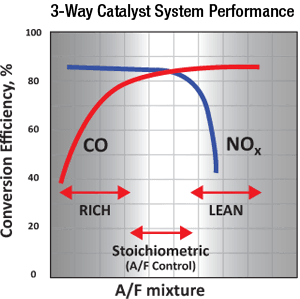

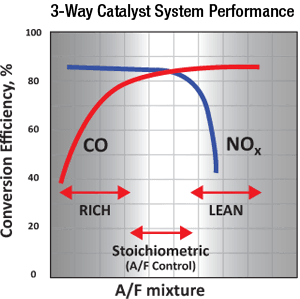

The BlueCAT™ 200 Air/Fuel Ratio Controller (A/F) is a closed-loop system and includes a zirconium oxygen (O2) sensor, fuel system control solenoid and an Electronic Control Unit (ECU). The ECU receives a feedback signal from the O2 sensor and modulates the solenoid to maintain the engine A/F ratio at the stoichiometric point, thereby maximizing catalyst performance.

The BlueCAT™ 200 Air/Fuel Ratio Controller (A/F) is a closed-loop system and includes a zirconium oxygen (O2) sensor, fuel system control solenoid and an Electronic Control Unit (ECU). The ECU receives a feedback signal from the O2 sensor and modulates the solenoid to maintain the engine A/F ratio at the stoichiometric point, thereby maximizing catalyst performance.

The fundamental reactions in a 3-Way Catalyst are between Carbon Monoxide (CO) and Hydrocarbons (HC) on one side and Oxides of Nitrogen (NOX) on the other. To achieve high conversions of all three emissions simultaneously, the A/F ratio must be at the stoichiometric ratio. Simply, this means the amount of CO and HC are in proportion with the amount of NOX present in the exhaust – these gases combine to form water, nitrogen and carbon dioxide.

BlueCAT™ 200 - Designs and Options

All models are a direct-fit replacement for the original muffler. Installation time and labor costs are reduced to a minimum. Over 5000 muffler designs are available for virtually any application. The BlueCAT™ 200 catalytic muffler matches or surpasses the noise attenuation performance of the original muffler.

The BlueCAT™ 200 system can control Air/Fuel mixtures on carbureted engines fueled by Liquefied Petroleum Gas (LPG, “propane”, “propane-butane”) and by Compressed Natural Gas (CNG). It is primarily designed to work with air-valve type gaseous carburetor systems, including IMPCO, Nolff’s, and equivalent products. The controller is also compatible with most venturi-type gaseous carburetors, such as Aisan, Beam, or Garretson.

The controller is not intended, nor legal for installation on gasoline fueled engines, or for use on engines with electronic fuel injection systems. To install either BlueCAT™ 200 system on a gasoline fueled engine it is first necessary to convert it to a carbureted LPG/CNG fuel system, after which installation can occur.

BlueCAT™ 200 - Verification

The BlueCAT™ 200 is a Retrofit Emissions Control System which has been verified by the California Air Resources Board (CARB) for installation on uncontrolled gaseous fueled Large Spark Ignited (LSI) engines.

System reduces emissions to 1.5 g/bhp-hr NOx + HC (2.0 g/kW-hr). It's verified for unregulated off-road LSI engines, model years 1990 to 2001 and non-complying phase-in off-road LSI engines model years 2001 through 2003. The engine must be 1.4 – 2.5 liters and use propane fuel.

You can find more details about the BlueCAT™ 200 verification on the official ARB website here.

BlueCAT™ 200 - Technology

The BlueCAT™ 200 is a Retrofit Emissions Control System which has been verified by the California Air Resources Board (CARB) for installation on uncontrolled gaseous fueled Large Spark Ignited (LSI) engines. BlueCAT™ 200 systems control exhaust emissions and noise from industrial forklift trucks and other spark ignited rich-burn (stoichiometric) engines. Nett Technologies’ BlueCAT™ 200 practically eliminates all of the major exhaust pollutants: Carbon Monoxide (CO), Hydrocarbons (HC) and Oxides of Nitrogen (NOx) from engine exhaust.

The BlueCAT™ 200 system consists of a 3-Way Catalytic Converter/Muffler, and a digital Air/Fuel Ratio Controller (A/F). The entire system is designed for quick and easy installation:

- an oxygen sensor port is built into the converter/muffler

- the self-diagnostic Electronic Control Unit (ECU) comes complete with all wiring and connectors

- comprehensive instructions, refined by hundreds of installations, are included

The BlueCAT™ 200 ECU is packaged in a rugged metal enclosure suitable for dash or engine compartment installation. The controller incorporates an on board diagnostic system, which allows constant monitoring of the operation and simplifies set-up. The combination of lights built directly into the unit provides an indication of controller operation without the need for additional monitoring tools. The diagnostic functions include a power and failure light, a warm up and O2 sensor light, and a set of lights to monitor the percentage of A/F ratio modulation. It also includes a dashboard-mountable warning light to alert the operator in case of system failure and to prevent the release of excessive emissions.

The BlueCAT™ 200 and BlueCAT™ 300 both use the same basic technology to operate, and are externally identical except for the identification plates. Internally the BlueCAT™ 300 uses a more advanced catalyst and slightly different tuning of the control circuitry for improved emissions reductions.

In cases when you have a forklift fleet, use our Large Spark Ignited (LSI) engine calculator and discover the available fleet emission control solutions.

BlueCAT™ 200 - Performance

The BlueCAT™ 200 Air/Fuel Ratio Controller (A/F) is a closed-loop system and includes a zirconium oxygen (O2) sensor, fuel system control solenoid and an Electronic Control Unit (ECU). The ECU receives a feedback signal from the O2 sensor and modulates the solenoid to maintain the engine A/F ratio at the stoichiometric point, thereby maximizing catalyst performance.

The BlueCAT™ 200 Air/Fuel Ratio Controller (A/F) is a closed-loop system and includes a zirconium oxygen (O2) sensor, fuel system control solenoid and an Electronic Control Unit (ECU). The ECU receives a feedback signal from the O2 sensor and modulates the solenoid to maintain the engine A/F ratio at the stoichiometric point, thereby maximizing catalyst performance.

The fundamental reactions in a 3-Way Catalyst are between Carbon Monoxide (CO) and Hydrocarbons (HC) on one side and Oxides of Nitrogen (NOX) on the other. To achieve high conversions of all three emissions simultaneously, the A/F ratio must be at the stoichiometric ratio. Simply, this means the amount of CO and HC are in proportion with the amount of NOX present in the exhaust – these gases combine to form water, nitrogen and carbon dioxide.

BlueCAT™ 200 - Designs and Options

All models are a direct-fit replacement for the original muffler. Installation time and labor costs are reduced to a minimum. Over 5000 muffler designs are available for virtually any application. The BlueCAT™ 200 catalytic muffler matches or surpasses the noise attenuation performance of the original muffler.

The BlueCAT™ 200 system can control Air/Fuel mixtures on carbureted engines fueled by Liquefied Petroleum Gas (LPG, “propane”, “propane-butane”) and by Compressed Natural Gas (CNG). It is primarily designed to work with air-valve type gaseous carburetor systems, including IMPCO, Nolff’s, and equivalent products. The controller is also compatible with most venturi-type gaseous carburetors, such as Aisan, Beam, or Garretson.

The controller is not intended, nor legal for installation on gasoline fueled engines, or for use on engines with electronic fuel injection systems. To install either BlueCAT™ 200 system on a gasoline fueled engine it is first necessary to convert it to a carbureted LPG/CNG fuel system, after which installation can occur.

BlueCAT™ 200 - Verification

The BlueCAT™ 200 is a Retrofit Emissions Control System which has been verified by the California Air Resources Board (CARB) for installation on uncontrolled gaseous fueled Large Spark Ignited (LSI) engines.

System reduces emissions to 1.5 g/bhp-hr NOx + HC (2.0 g/kW-hr). It's verified for unregulated off-road LSI engines, model years 1990 to 2001 and non-complying phase-in off-road LSI engines model years 2001 through 2003. The engine must be 1.4 – 2.5 liters and use propane fuel.

You can find more details about the BlueCAT™ 200 verification on the official ARB website here.

Add-On Products

BlueCAT™ 200 A/F Ratio Controller

California Air Resource Board (CARB) verified system

California Air Resource Board (CARB) verified system