T-Series

3-Way Catalytic Converters Features

- 3-Way Catalytic Converter designed to operate on gasoline and gaseous (LPG & CNG) fueled Large Spark Ignited (LSI) engines

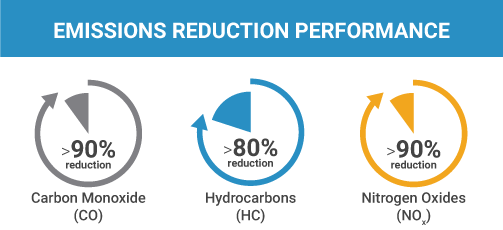

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC) and Oxides of Nitrogen (NOx)

- Ideal for construction, material handling, mining, on-road, power generation, and utility industries

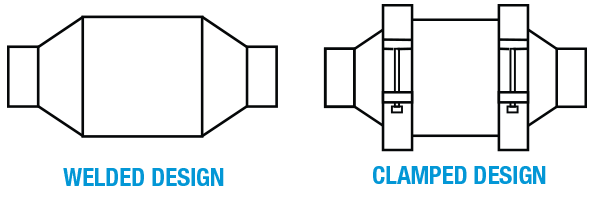

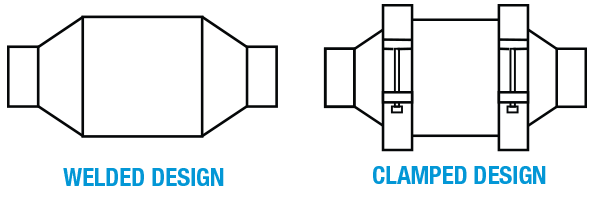

- Available in two designs: as a direct-fit replacement for the original muffler and as an in-line converter (standard fit)

- Customized designs are available upon request

- T-Series catalytic muffler matches or surpasses the original muffler in sound attenuation and backpressure characteristics with the addition of superior emissions performance

- Mufflers are built entirely from corrosion-resistant materials: aluminized and stainless steels

- It’s compatible with an A/F controller (optional) to maximize the emission reduction in gaseous-fueled engines

T-Series - Technology

Nett Technologies' catalytic mufflers have been designed to control exhaust emissions and noise from industrial forklift trucks as well as other spark ignited engines used in material handling and construction. The emission control system and the noise attenuation components are incorporated in one shell. All Nett Technology catalytic mufflers are designed to match the noise attenuation of the original mufflers they replace.

Three-Way catalytic mufflers are the most effective way of controlling Carbon Monoxide, Hydrocarbons, and Nitrogen Oxides emissions from LPG, CNG, and gasoline engines. CO and NOx emissions can be simultaneously reduced by 90-99%. Three-way catalyst systems are available in two configurations:

|

|

| Closed-Loop Control System. The complete system (shown in green) includes a catalytic muffler with built-in Three-Way catalyst, a zirconium oxygen sensor, and an electronic control unit (ECU). The ECU receives a feedback signal from the O2 sensor and maintains the engine air/fuel ratio at the stoichiometric point, which yields optimal catalyst performance. This system provides the best conversion of both Carbon Monoxide and Nitrogen Oxides and can improve the fuel economy of the truck. Whenever NOx control is important, use of the closed-loop system is strongly recommended. | Open-Loop Control System. The catalytic muffler with a built-in three-way catalyst is installed directly into the existing exhaust system. This layout is recommended when CO control is required but NOx performance can be compromised. The performance of the catalyst will vary depending on the engine A/F ratio (see performance chart in the "Emissions FAQ" section). Operating the truck at a slightly lean mixture will result in good CO abatement. The overall effect greatly depends on the engine maintenance program. |

T-Series - Performance

In Nett Technologies' T-Series 3-way catalyst, reactions between Carbon Monoxide (CO), Hydrocarbons (HC), and Oxides of Nitrogen (NOx) result in the simultaneous removal of all three major exhaust pollutants. One of the fundamental chemical reactions occurring in the catalyst can be written as follows: CO + NO = CO2 + 1/2 N2 Concentrations of pollutants in the exhaust gas depend on the fuel mixture composition. At lean fuel mixtures the exhaust gases contain little Carbon Monoxide (CO) or Hydrocarbons (HC) but high concentrations of Oxides of Nitrogen (NOx). Rich mixtures produce high concentrations of CO and HC with little NOx. In order to achieve high simultaneous conversions of CO and NOx, their concentrations in the exhaust must be in stoichiometric proportion, as illustrated by the above equation. If the air-to-fuel mixture is not stoichiometric, conversion of either NOx or CO will deteriorate, as shown in the diagram below. Carbon Monoxide emissions are typically reduced by over 90%. Hydrocarbons are reduced by 80%. The characteristic smell of propane exhaust is virtually eliminated. Over 90% reduction of nitrogen oxides is achieved when Nett's BlueCAT™100 air/fuel ratio controller is used.T-Series - Designs & Options

Standard and Custom Models

Direct-Fit Catalytic Mufflers

Nett Technologies has direct-fit catalytic mufflers available for hundreds of models of forklift trucks and other LPG powered equipment. The pre-designed models are in-stock or can be built and shipped within a few days. Catalytic mufflers are available to replace the original muffler for any LPG application. The emission control catalyst is built into the muffler and is selected based on the size of the engine. Catalytic mufflers are guaranteed to be a exact-fit replacement for the original muffler. The emissions reduction performance of catalytic mufflers is also guaranteed, provided the engine is well maintained and no excessive CO emissions are present.

Universal-Fit Catalytic Converters

For applications where a catalytic muffler is not required or desired, universal-fit catalytic converters are available. These in-stock, ready to ship products are available in a variety of sizes and with a range of inlet/outlet pipe diameters. Installation is not as easy as with direct-fit products but simply involves cutting-out a section of the equipment’s exhaust pipe and installing the catalytic converter in its place. The section of exhaust pipe chosen must be straight with sufficient clearance on all sides and be located upstream of the muffler.

OEM Products

OEM applications are developed in co-operation with the equipment manufacturer. The catalyst specifications are optimized to meet the particular emission targets and durability requirements. As well, the design of the muffler, including the catalyst substrate selection, canning technology, and noise attenuation requirements are optimized for the application. Development of OEM exhaust systems includes the design and fabrication of prototypes which are tested for emission and noise performance. Nett also provides compliance certification with the EPA or California ARB (Air Resources Board) regardless of whether a Nett emission control device is utilized. Three emission test cells are available for exhaust analysis of LPG, gasoline, CNG or diesel engines up to 250 kW (335 hp). See Engine Emissions Test Laboratory section for more information.

T-Series - Technology

Nett Technologies' catalytic mufflers have been designed to control exhaust emissions and noise from industrial forklift trucks as well as other spark ignited engines used in material handling and construction. The emission control system and the noise attenuation components are incorporated in one shell. All Nett Technology catalytic mufflers are designed to match the noise attenuation of the original mufflers they replace.

Three-Way catalytic mufflers are the most effective way of controlling Carbon Monoxide, Hydrocarbons, and Nitrogen Oxides emissions from LPG, CNG, and gasoline engines. CO and NOx emissions can be simultaneously reduced by 90-99%. Three-way catalyst systems are available in two configurations:

|

|

| Closed-Loop Control System. The complete system (shown in green) includes a catalytic muffler with built-in Three-Way catalyst, a zirconium oxygen sensor, and an electronic control unit (ECU). The ECU receives a feedback signal from the O2 sensor and maintains the engine air/fuel ratio at the stoichiometric point, which yields optimal catalyst performance. This system provides the best conversion of both Carbon Monoxide and Nitrogen Oxides and can improve the fuel economy of the truck. Whenever NOx control is important, use of the closed-loop system is strongly recommended. | Open-Loop Control System. The catalytic muffler with a built-in three-way catalyst is installed directly into the existing exhaust system. This layout is recommended when CO control is required but NOx performance can be compromised. The performance of the catalyst will vary depending on the engine A/F ratio (see performance chart in the "Emissions FAQ" section). Operating the truck at a slightly lean mixture will result in good CO abatement. The overall effect greatly depends on the engine maintenance program. |

T-Series - Performance

In Nett Technologies' T-Series 3-way catalyst, reactions between Carbon Monoxide (CO), Hydrocarbons (HC), and Oxides of Nitrogen (NOx) result in the simultaneous removal of all three major exhaust pollutants. One of the fundamental chemical reactions occurring in the catalyst can be written as follows: CO + NO = CO2 + 1/2 N2 Concentrations of pollutants in the exhaust gas depend on the fuel mixture composition. At lean fuel mixtures the exhaust gases contain little Carbon Monoxide (CO) or Hydrocarbons (HC) but high concentrations of Oxides of Nitrogen (NOx). Rich mixtures produce high concentrations of CO and HC with little NOx. In order to achieve high simultaneous conversions of CO and NOx, their concentrations in the exhaust must be in stoichiometric proportion, as illustrated by the above equation. If the air-to-fuel mixture is not stoichiometric, conversion of either NOx or CO will deteriorate, as shown in the diagram below. Carbon Monoxide emissions are typically reduced by over 90%. Hydrocarbons are reduced by 80%. The characteristic smell of propane exhaust is virtually eliminated. Over 90% reduction of nitrogen oxides is achieved when Nett's BlueCAT™100 air/fuel ratio controller is used.T-Series - Designs & Options

Standard and Custom Models

Direct-Fit Catalytic Mufflers

Nett Technologies has direct-fit catalytic mufflers available for hundreds of models of forklift trucks and other LPG powered equipment. The pre-designed models are in-stock or can be built and shipped within a few days. Catalytic mufflers are available to replace the original muffler for any LPG application. The emission control catalyst is built into the muffler and is selected based on the size of the engine. Catalytic mufflers are guaranteed to be a exact-fit replacement for the original muffler. The emissions reduction performance of catalytic mufflers is also guaranteed, provided the engine is well maintained and no excessive CO emissions are present.

Universal-Fit Catalytic Converters

For applications where a catalytic muffler is not required or desired, universal-fit catalytic converters are available. These in-stock, ready to ship products are available in a variety of sizes and with a range of inlet/outlet pipe diameters. Installation is not as easy as with direct-fit products but simply involves cutting-out a section of the equipment’s exhaust pipe and installing the catalytic converter in its place. The section of exhaust pipe chosen must be straight with sufficient clearance on all sides and be located upstream of the muffler.

OEM Products

OEM applications are developed in co-operation with the equipment manufacturer. The catalyst specifications are optimized to meet the particular emission targets and durability requirements. As well, the design of the muffler, including the catalyst substrate selection, canning technology, and noise attenuation requirements are optimized for the application. Development of OEM exhaust systems includes the design and fabrication of prototypes which are tested for emission and noise performance. Nett also provides compliance certification with the EPA or California ARB (Air Resources Board) regardless of whether a Nett emission control device is utilized. Three emission test cells are available for exhaust analysis of LPG, gasoline, CNG or diesel engines up to 250 kW (335 hp). See Engine Emissions Test Laboratory section for more information.

Downloadable Documents

Catalytic Mufflers Brochure

Catalytic Mufflers Fact Sheet

Installation Guide

Installation Guide (Direct-Fit)

Installation Guide (Universal-Fit)

Photo Gallery