GreenTRAP™ d-Series

Passive DPF and DOC System Features

- The system consists of a passive Diesel Particulate Filter (DPF) and Diesel Oxidation Catalyst (DOC) to maximize the emission reduction performance

- GreenTRAP™ 100d is ideal for Off-road application (construction, mining, material handling), GreenTRAP™ 200d – On-road, GreenTRAP™ 300d – Power Generation, GreenTRAP™ 320d – Marine, GreenTRAP™ 350d – Gantry Cranes, GreenTRAP™ 420d – Locomotive industry

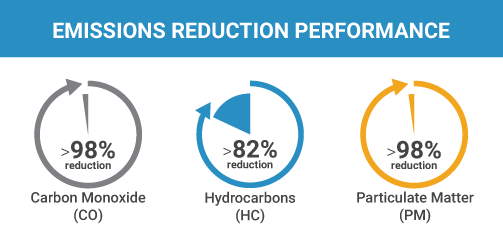

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC) and Particulate Matter (PM)

- Compact design with thermal insulation

- Optional computerized controller with 3 customizable alarms and data logging capabilities

- System maintenance intervals of 2000 to 6000 hours

- Stainless steel housing, custom fit available

- Optional bypass valve

GreenTRAP™ d-Series - Technology

Nett Technologies’ GreenTRAP™ d-Series is a passive Diesel Particulate Filter (DPF) system that is designed to control Particulate Matter (PM) emissions from diesel engines in stationary, off-road and on-road applications. It’s equipped with an upstream Diesel Oxidation Catalyst (DOC) to simultaneously oxidize Carbon Monoxide (CO), Hydrocarbon (HC) and aldehydes contained in diesel exhaust to non-toxic compounds: carbon dioxide and water vapor. The GreenTRAP™ d-Series system utilizes cordierite wall-flow monoliths to trap the soot produced by diesel engines. A proprietary catalyst is coated onto the inside surface of the filter monolith which lowers the soot combustion temperature allowing the filter to self-clean (regenerate) at lower exhaust temperatures. All of the accumulated soot inside the filter can, therefore, be oxidized during regular operation of the engine. In favorable operational conditions, the system has a 98% PM reduction. In addition, the system will reduce CO and HC emissions greater than 98% and 82% respectively.

The GreenTRAP™ d-Series system is customized to fit your specific application, providing you full control over PM, rather than allowing PM to control you.

GreenTRAP™ d-Series - Performance

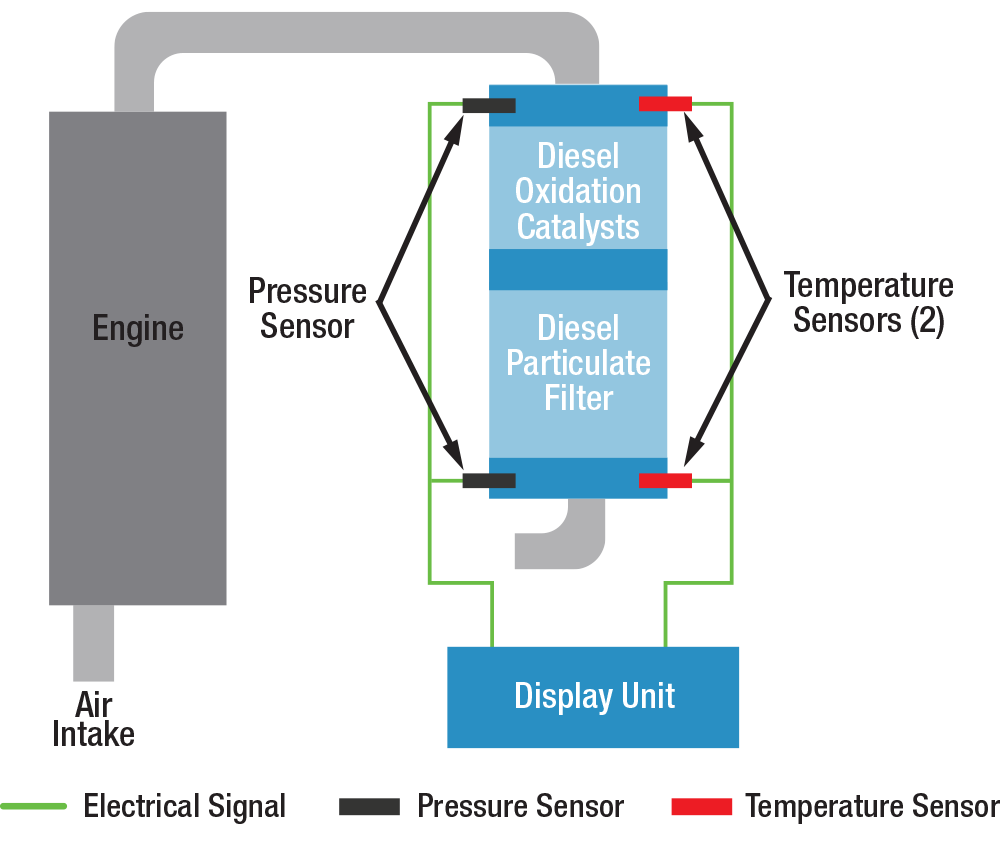

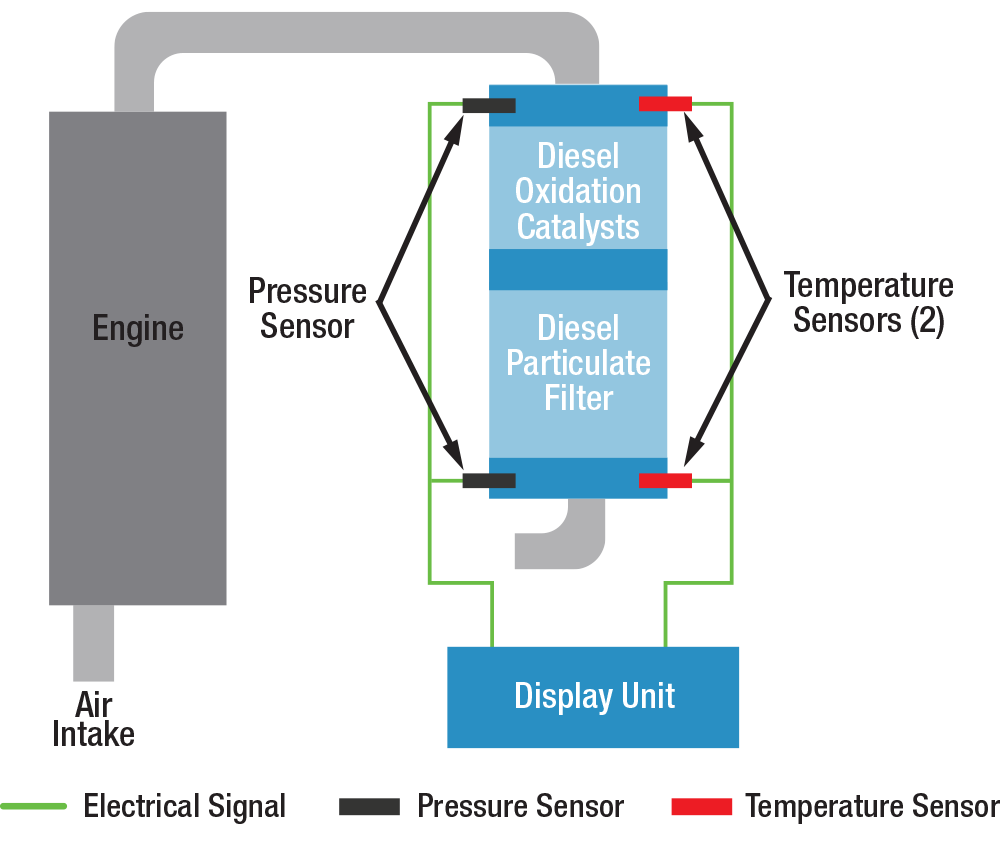

Nett Technologies’ GreenTRAP™ d-Series system includes a passive Diesel Particulate Filter (DPF) system equipped with an upstream Diesel Oxidation Catalyst (DOC). The system and its main components are depicted below. The system utilizes cordierite wall-flow monoliths to trap the soot produced by diesel engines. The cylindrical filter element consists of many parallel channels running in the axial direction, separated by thin porous walls. The channels are open at one end and plugged at the other, forcing the particle laden exhaust gases to flow through the walls. Gases are able to escape through the pores in the wall material, particulates, however, are too large to escape and are trapped inside the filter. A proprietary catalyst is coated onto the inside surface of the filter monolith. The catalyst lowers the soot combustion temperature allowing the filter to regenerate at lower exhaust temperatures. The accumulated soot inside the filter can, therefore, be oxidized during regular operation of the engine. Exhaust temperatures of 250-300° C (482-572 °F) for 25-30% of the operation time are necessary for proper filter regeneration when ultra-low sulfur diesel (ULSD) fuel is used. This can be met on most heavy-duty diesel engine applications, as well as on some medium and light-duty engines. Nett filters can be used with all fuels, with preferably no more than 50ppm sulfur content, however, higher exhaust temperatures will be required for regeneration. The GreenTRAP™ d-Series utilizes a precious metal coated DOC upstream of the DPF unit. The DOC core is made of corrugated, high temperature resistant stainless steel foil, packaged into rugged stainless steel containers. A monitoring system along with 2 temperature sensors and 1 differential pressure sensor can be used to monitor and datalog the DPF backpressure and DOC/DPF inlet/outlet temperatures in real time. The monitoring system will notify the operator of possible system issues and will and ensure a problem-free operation during the whole life span of the system.GreenTRAP™ d-Series System Schematic Drawing

GreenTRAP™ d-Series - Designs and Options

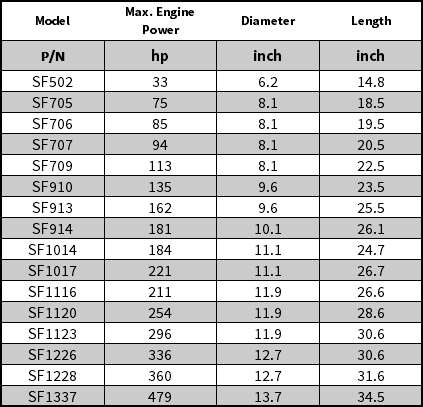

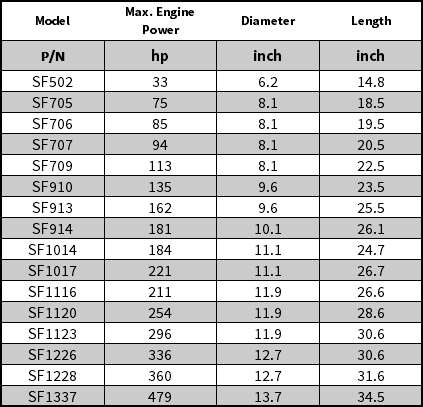

Standard models of cordierite and Silicon Carbide Diesel Particulate Filters (DPFs) are listed in Table 1 and Table 2, respectively. Filter sizing guidelines in the table are approximate. Please contact us for sizing of particular engines and applications before ordering.

Nett Diesel Particulate Filters: Cordierite Substrates (SF)

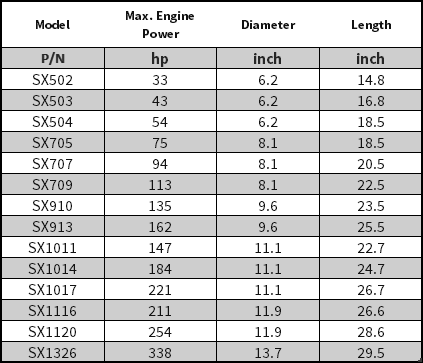

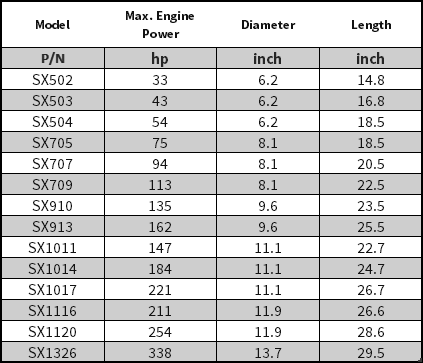

Nett Diesel Particulate Filters: Silicon Carbide (SiC) Substrates (SX)

GreenTRAP™ d-Series - Technology

Nett Technologies’ GreenTRAP™ d-Series is a passive Diesel Particulate Filter (DPF) system that is designed to control Particulate Matter (PM) emissions from diesel engines in stationary, off-road and on-road applications. It’s equipped with an upstream Diesel Oxidation Catalyst (DOC) to simultaneously oxidize Carbon Monoxide (CO), Hydrocarbon (HC) and aldehydes contained in diesel exhaust to non-toxic compounds: carbon dioxide and water vapor. The GreenTRAP™ d-Series system utilizes cordierite wall-flow monoliths to trap the soot produced by diesel engines. A proprietary catalyst is coated onto the inside surface of the filter monolith which lowers the soot combustion temperature allowing the filter to self-clean (regenerate) at lower exhaust temperatures. All of the accumulated soot inside the filter can, therefore, be oxidized during regular operation of the engine. In favorable operational conditions, the system has a 98% PM reduction. In addition, the system will reduce CO and HC emissions greater than 98% and 82% respectively.

The GreenTRAP™ d-Series system is customized to fit your specific application, providing you full control over PM, rather than allowing PM to control you.

GreenTRAP™ d-Series - Performance

Nett Technologies’ GreenTRAP™ d-Series system includes a passive Diesel Particulate Filter (DPF) system equipped with an upstream Diesel Oxidation Catalyst (DOC). The system and its main components are depicted below. The system utilizes cordierite wall-flow monoliths to trap the soot produced by diesel engines. The cylindrical filter element consists of many parallel channels running in the axial direction, separated by thin porous walls. The channels are open at one end and plugged at the other, forcing the particle laden exhaust gases to flow through the walls. Gases are able to escape through the pores in the wall material, particulates, however, are too large to escape and are trapped inside the filter. A proprietary catalyst is coated onto the inside surface of the filter monolith. The catalyst lowers the soot combustion temperature allowing the filter to regenerate at lower exhaust temperatures. The accumulated soot inside the filter can, therefore, be oxidized during regular operation of the engine. Exhaust temperatures of 250-300° C (482-572 °F) for 25-30% of the operation time are necessary for proper filter regeneration when ultra-low sulfur diesel (ULSD) fuel is used. This can be met on most heavy-duty diesel engine applications, as well as on some medium and light-duty engines. Nett filters can be used with all fuels, with preferably no more than 50ppm sulfur content, however, higher exhaust temperatures will be required for regeneration. The GreenTRAP™ d-Series utilizes a precious metal coated DOC upstream of the DPF unit. The DOC core is made of corrugated, high temperature resistant stainless steel foil, packaged into rugged stainless steel containers. A monitoring system along with 2 temperature sensors and 1 differential pressure sensor can be used to monitor and datalog the DPF backpressure and DOC/DPF inlet/outlet temperatures in real time. The monitoring system will notify the operator of possible system issues and will and ensure a problem-free operation during the whole life span of the system.GreenTRAP™ d-Series System Schematic Drawing

GreenTRAP™ d-Series - Designs and Options

Standard models of cordierite and Silicon Carbide Diesel Particulate Filters (DPFs) are listed in Table 1 and Table 2, respectively. Filter sizing guidelines in the table are approximate. Please contact us for sizing of particular engines and applications before ordering.

Nett Diesel Particulate Filters: Cordierite Substrates (SF)

Nett Diesel Particulate Filters: Silicon Carbide (SiC) Substrates (SX)

Photo Gallery