BlueMAX™ d-Series

SCR and DOC System Features

- The system consists of a Selective Catalytic Reduction (SCR) and Diesel Oxidation Catalyst (DOC)

- BlueMAX™ 100d is ideal for Off-road application (construction, mining, material handling), BlueMAX™ 200d – On-road, BlueMAX™ 300d – Power Generation, BlueMAX™ 320d – Marine, BlueMAX™ 350d – Gantry Cranes, BlueMAX™ 420d – Locomotive industry

- EPA verified for 100-750hp engines in the stationary application (BlueMAX™ 300d)

- Great at reducing deadly emissions, such as Carbon Monoxide (CO), Hydrocarbons (HC) and Nitrogen Oxides (NOx) emissions from your diesel engine

- Optional computerized controller with 3 customizable alarms and data logging capabilities

- System maintenance intervals of 2000 to 5000 hours

- Data logging capabilities

- Colour display informing of system operating conditions and status

- Stainless steel housing, custom fit available

BlueMAX™ d-Series - Technology

The BlueMAX™ d-Series is a Nitrogen Oxides (NOx) control system that is designed for medium to heavy-duty diesel engines in stationary, off-road and on-road applications. It consists of a Diesel Oxidation Catalyst (DOC) upstream of a Selective Catalytic Reduction (SCR) system and typically provides a reduction in NOx emissions in the range of 65 to 90% under transient diesel engine conditions and over 90% in steady-state operation.

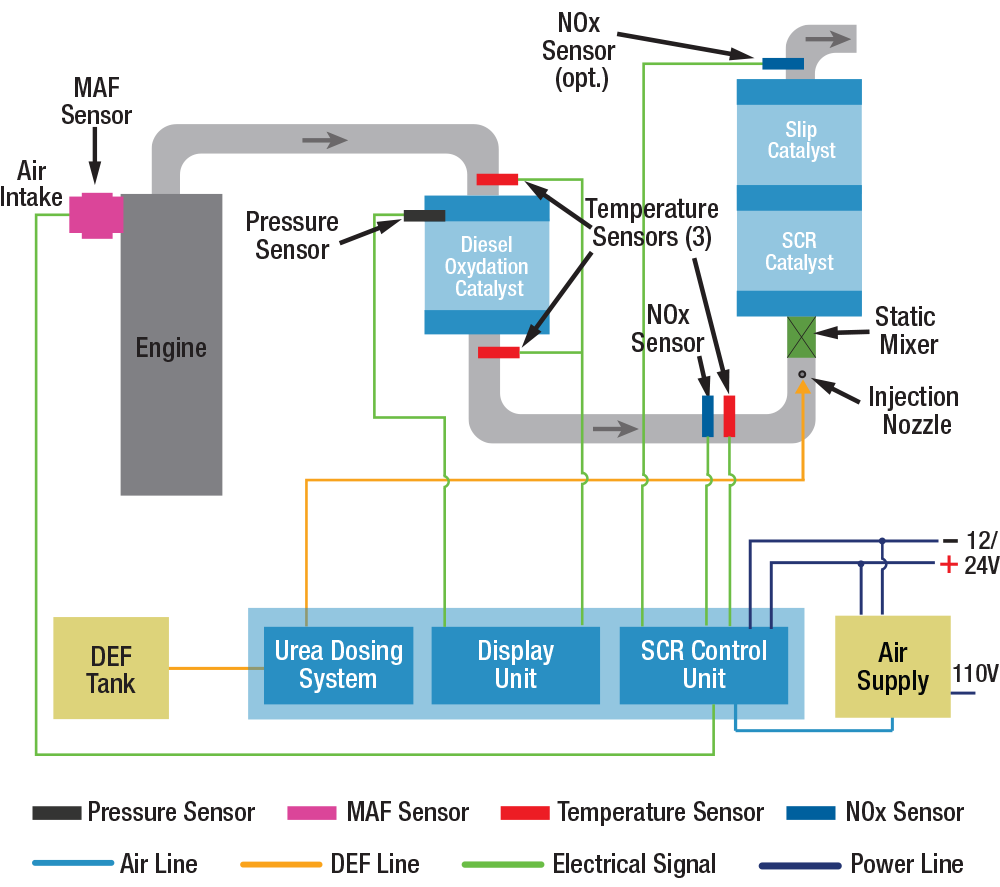

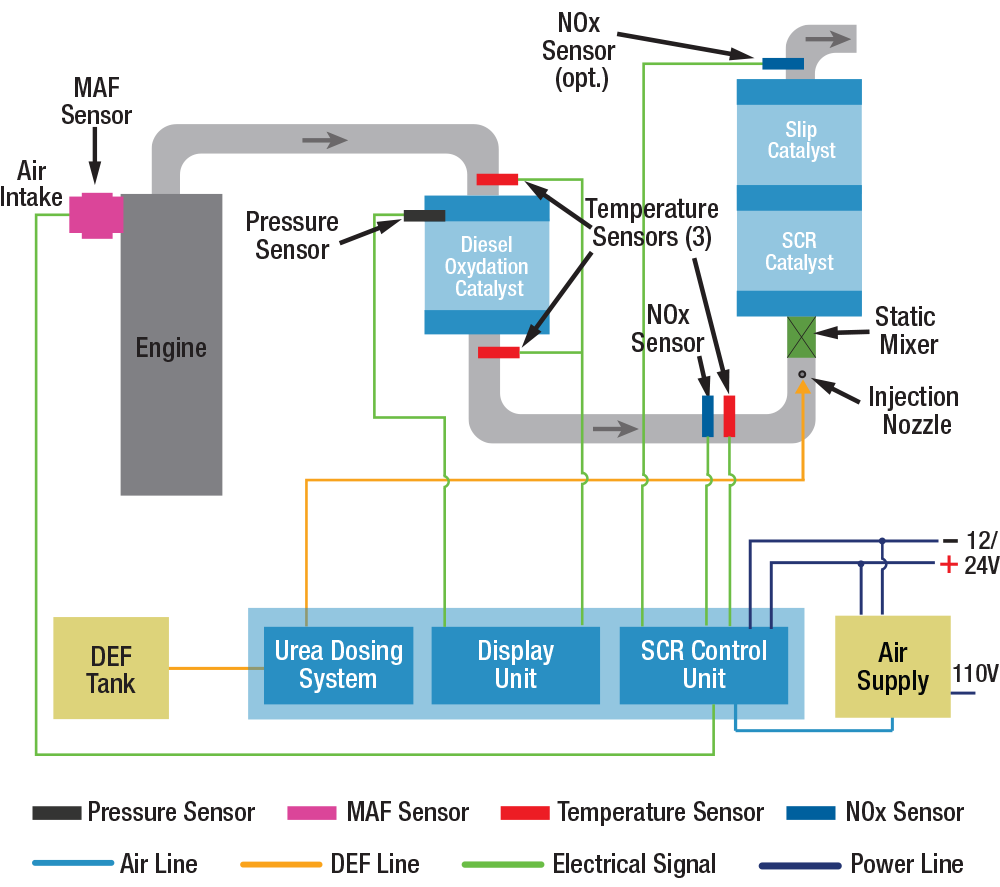

In the BlueMAX™ d-Series system, NOx is reduced over the SCR catalyst through a chemical reaction with Diesel Exhaust Fluid (DEF). The SCR sub-system consists of a SCR catalytic converter, a DEF dosing unit, and a DEF tank (see diagram). The DEF control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine mass air flow sensor and temperature sensors, the Electronic Control Unit (ECU) calculates the amount of urea which needs to be injected for optimum NOx reduction. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

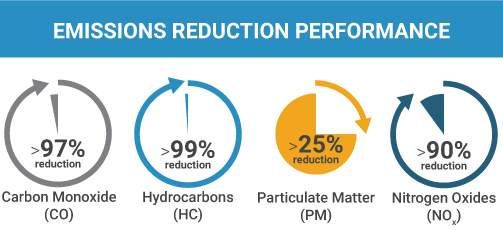

The Nett Technologies’ BlueMAX™ d-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display. In addition to 90% NOx reduction, the system also provides a reduction in Particulate Matter (PM) greater than 25%, Carbon Monoxide (CO) greater than 97%, and Hydrocarbons (HC) greater than 99% from the engine exhaust.

BlueMAX™ d-Series - Performance

The Nett Technologies’ BlueMAX™ d-Series system is designed to control the emissions of Nitrogen Oxides (NOx) from medium and heavy-duty diesel engines in stationary, off-road and on-road applications. In Selective Catalytic Reduction (SCR) technology, Oxides of Nitrogen (NOx) is reduced over the SCR catalyst through a chemical reaction with a reducing agent, either ammonia (NH3) or urea. For safe and easy handling the BlueMAX™ d-Series system utilizes urea for its operation. The main components of the BlueMAX™ d-Series system include the SCR catalytic converter, the computerized Urea Dosing System (UDS), Diesel Oxidation Catalyst (DOC) and the urea tank (see diagram). The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine air mass ow sensor and temperature sensors, the computer calculates the amount of urea which needs to be injected for optimum NOx reductions. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled. Urea (in the form of a 32.5% water-based solution) is metered by a computer controlled dosing pump into the exhaust pipe upstream of the SCR catalyst through an injection nozzle. Compressed air from the air brake line or a standalone air compressor is used to atomize the urea for optimum dispersion, to maximize NOx reduction and to minimize the amount of urea required. The BlueMAX™ d-Series utilizes a precious metal coated DOC upstream of the SCR unit. The DOC core is made of corrugated, high temperature resistant stainless steel foil, packaged into rugged stainless steel containers. The DOC oxidizes Carbon Monoxide (CO), Hydrocarbons (HC) and aldehydes contained in diesel exhaust to non-toxic compounds: carbon dioxide and water vapor. The BlueMAX™ d-Series system is verified by US Environmental Protection Agency (EPA) for medium and heavy duty diesel engines in stationary applications.BlueMAX™ d-Series System Schematic Drawing

BlueMAX™ d-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ d-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ d-Series Standard Models (GT)

| Max. Engine Power | ||

| Model | hp | kW |

| GT5100 | 100 | 75 |

| GT5200 | 150 | 110 |

| GT5300 | 200 | 150 |

| GT5400 | 250 | 185 |

| GT5500 | 300 | 225 |

| GT5600 | 350 | 260 |

| GT5700 | 400 | 300 |

| GT5800 | 450 | 335 |

| GT5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ d-Series Selective Catalytic Reduction (SCR) and Diesel Oxidation Catalyst (DOC) system is typically installed under-hood, retaining the equipment's factory appearance and operator sight-lines.

BlueMAX™ 300d - EPA Verification

Nett’s BlueMAX™ 300d SCR is an emission control system that has been designed to reduce Nitrogen Oxides (NOx) emissions by at least 80% from medium- and heavy-duty diesel engines between 75 and 560 kW (100-750 hp) in portable and stationary applications like diesel generator sets, pumps and compressors. The system also has the added benefit of reducing criteria emissions of Carbon Monoxide (CO) and Hydrocarbons (HC) by at least 90% and Particulate Matter (PM) by at least 25%. This product is especially well suited for the known ozone nonattainment areas where controlling NOx will help individual states to adopt appropriate State Implementation Plans (SIPs) under the Clean Air Act.

Criteria to achieve emission reductions

The following criteria must be met in order for appropriately retrofitted engines to achieve the aforementioned emission reductions:

- Baseline engine must be in a certified configuration and operating on fuel with less than 15 ppm sulfur.

- Exhaust temperature data logging will be performed before each installation, and exhaust temperatures must be above 225 degrees °C for at least 30% of the normal duty cycle. As there may be significant variations from application to application, Nett Technologies will review actual engine operating conditions and perform temperature data-logging prior to retrofitting an engine with the SCR system to ensure compatibility.

- Each installation will be equipped with a monitoring system that displays warning lights and error codes visible to the operator, providing urea tank level and diagnostic information.

- The engine/equipment must not be equipped with a crankcase oil burning system.

- The engine should be well maintained and not consume lubricating oil at a rate greater than that specified by the engine manufacturer.

- The engine must not have been originally certified or equipped with a DOC or diesel particulate

- For constant speed engines in stationary applications, Nett Technology Inc. is responsible for working with end-users in determining the engine’s eligibility and compliance with applicable federal, state, and/or local regulations.

For more information about the system verification, please visit EPA website: https://www.epa.gov/verified-diesel-tech/nett-technologies-inc-bluemaxtm-300d-selective-catalytic-reduction-scr-system

BlueMAX™ d-Series - Technology

The BlueMAX™ d-Series is a Nitrogen Oxides (NOx) control system that is designed for medium to heavy-duty diesel engines in stationary, off-road and on-road applications. It consists of a Diesel Oxidation Catalyst (DOC) upstream of a Selective Catalytic Reduction (SCR) system and typically provides a reduction in NOx emissions in the range of 65 to 90% under transient diesel engine conditions and over 90% in steady-state operation.

In the BlueMAX™ d-Series system, NOx is reduced over the SCR catalyst through a chemical reaction with Diesel Exhaust Fluid (DEF). The SCR sub-system consists of a SCR catalytic converter, a DEF dosing unit, and a DEF tank (see diagram). The DEF control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine mass air flow sensor and temperature sensors, the Electronic Control Unit (ECU) calculates the amount of urea which needs to be injected for optimum NOx reduction. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled.

The Nett Technologies’ BlueMAX™ d-Series ECU continuously monitors and measures the performance of all system sensors and components. In the event of a malfunction, the ECU will indicate the existence of a problem to the operator via the system display. In addition to 90% NOx reduction, the system also provides a reduction in Particulate Matter (PM) greater than 25%, Carbon Monoxide (CO) greater than 97%, and Hydrocarbons (HC) greater than 99% from the engine exhaust.

BlueMAX™ d-Series - Performance

The Nett Technologies’ BlueMAX™ d-Series system is designed to control the emissions of Nitrogen Oxides (NOx) from medium and heavy-duty diesel engines in stationary, off-road and on-road applications. In Selective Catalytic Reduction (SCR) technology, Oxides of Nitrogen (NOx) is reduced over the SCR catalyst through a chemical reaction with a reducing agent, either ammonia (NH3) or urea. For safe and easy handling the BlueMAX™ d-Series system utilizes urea for its operation. The main components of the BlueMAX™ d-Series system include the SCR catalytic converter, the computerized Urea Dosing System (UDS), Diesel Oxidation Catalyst (DOC) and the urea tank (see diagram). The urea control strategy relies on NOx concentration measurements by a sensor positioned upstream of the SCR catalyst. Based on the NOx sensor signal in combination with an engine air mass ow sensor and temperature sensors, the computer calculates the amount of urea which needs to be injected for optimum NOx reductions. The NOx sensor-based control strategy makes the system very suitable for both original equipment and retrofit applications. System calibration (i.e. engine mapping) is not required and the system can be installed on a wide range of diesel engines, both mechanically and electronically controlled. Urea (in the form of a 32.5% water-based solution) is metered by a computer controlled dosing pump into the exhaust pipe upstream of the SCR catalyst through an injection nozzle. Compressed air from the air brake line or a standalone air compressor is used to atomize the urea for optimum dispersion, to maximize NOx reduction and to minimize the amount of urea required. The BlueMAX™ d-Series utilizes a precious metal coated DOC upstream of the SCR unit. The DOC core is made of corrugated, high temperature resistant stainless steel foil, packaged into rugged stainless steel containers. The DOC oxidizes Carbon Monoxide (CO), Hydrocarbons (HC) and aldehydes contained in diesel exhaust to non-toxic compounds: carbon dioxide and water vapor. The BlueMAX™ d-Series system is verified by US Environmental Protection Agency (EPA) for medium and heavy duty diesel engines in stationary applications.BlueMAX™ d-Series System Schematic Drawing

BlueMAX™ d-Series - Designs and Options

Standard models and sizing charts for the Nett BlueMAX™ d-Series system are listed in Table 1. Sizing for particular engines and applications should be consulted with our office before ordering.

Nett BlueMAX™ d-Series Standard Models (GT)

| Max. Engine Power | ||

| Model | hp | kW |

| GT5100 | 100 | 75 |

| GT5200 | 150 | 110 |

| GT5300 | 200 | 150 |

| GT5400 | 250 | 185 |

| GT5500 | 300 | 225 |

| GT5600 | 350 | 260 |

| GT5700 | 400 | 300 |

| GT5800 | 450 | 335 |

| GT5900 | 500 | 370 |

Custom housing designs are available to fit any engine configuration. The Nett BlueMAX™ d-Series Selective Catalytic Reduction (SCR) and Diesel Oxidation Catalyst (DOC) system is typically installed under-hood, retaining the equipment's factory appearance and operator sight-lines.

BlueMAX™ 300d - EPA Verification

Nett’s BlueMAX™ 300d SCR is an emission control system that has been designed to reduce Nitrogen Oxides (NOx) emissions by at least 80% from medium- and heavy-duty diesel engines between 75 and 560 kW (100-750 hp) in portable and stationary applications like diesel generator sets, pumps and compressors. The system also has the added benefit of reducing criteria emissions of Carbon Monoxide (CO) and Hydrocarbons (HC) by at least 90% and Particulate Matter (PM) by at least 25%. This product is especially well suited for the known ozone nonattainment areas where controlling NOx will help individual states to adopt appropriate State Implementation Plans (SIPs) under the Clean Air Act.

Criteria to achieve emission reductions

The following criteria must be met in order for appropriately retrofitted engines to achieve the aforementioned emission reductions:

- Baseline engine must be in a certified configuration and operating on fuel with less than 15 ppm sulfur.

- Exhaust temperature data logging will be performed before each installation, and exhaust temperatures must be above 225 degrees °C for at least 30% of the normal duty cycle. As there may be significant variations from application to application, Nett Technologies will review actual engine operating conditions and perform temperature data-logging prior to retrofitting an engine with the SCR system to ensure compatibility.

- Each installation will be equipped with a monitoring system that displays warning lights and error codes visible to the operator, providing urea tank level and diagnostic information.

- The engine/equipment must not be equipped with a crankcase oil burning system.

- The engine should be well maintained and not consume lubricating oil at a rate greater than that specified by the engine manufacturer.

- The engine must not have been originally certified or equipped with a DOC or diesel particulate

- For constant speed engines in stationary applications, Nett Technology Inc. is responsible for working with end-users in determining the engine’s eligibility and compliance with applicable federal, state, and/or local regulations.

For more information about the system verification, please visit EPA website: https://www.epa.gov/verified-diesel-tech/nett-technologies-inc-bluemaxtm-300d-selective-catalytic-reduction-scr-system